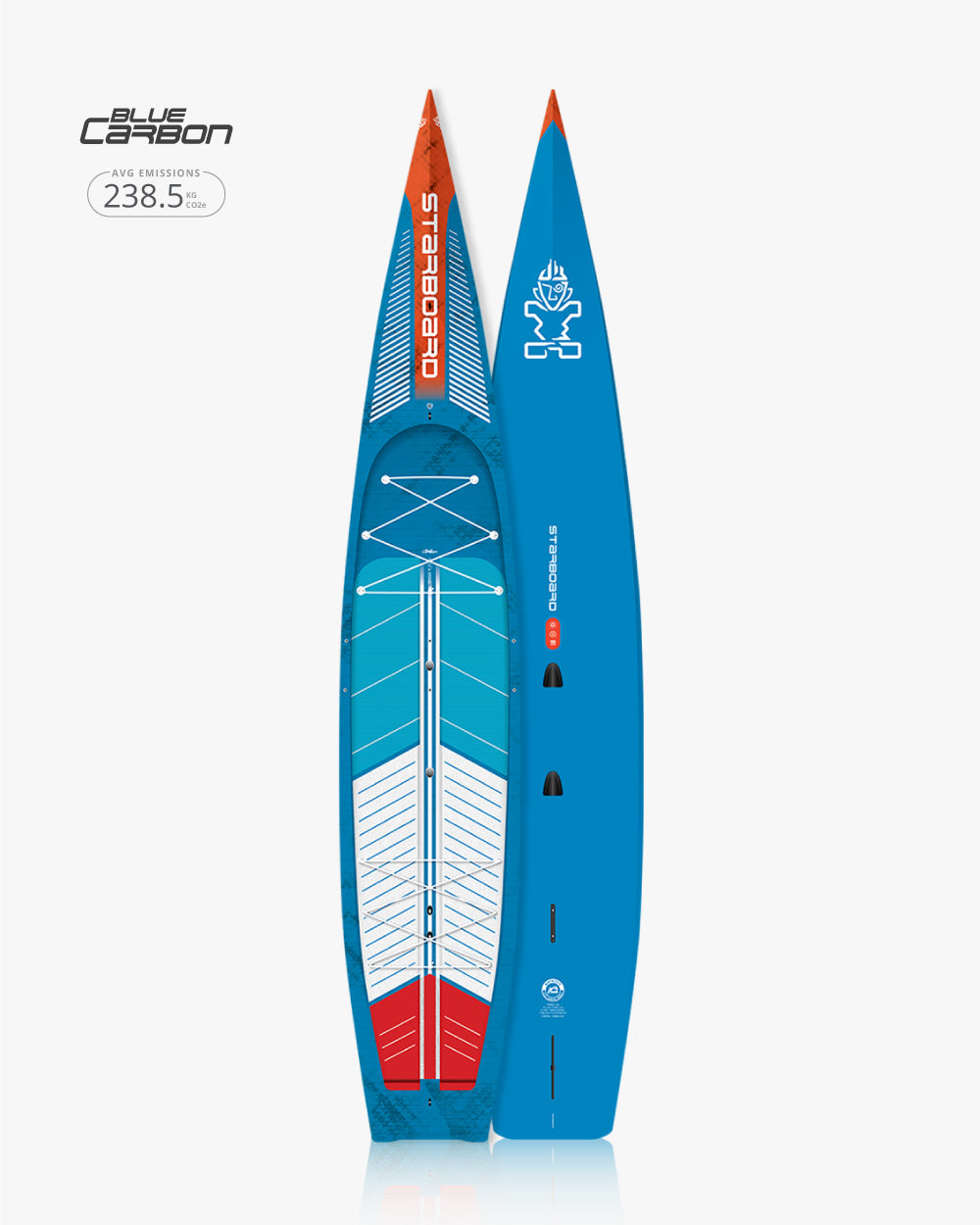

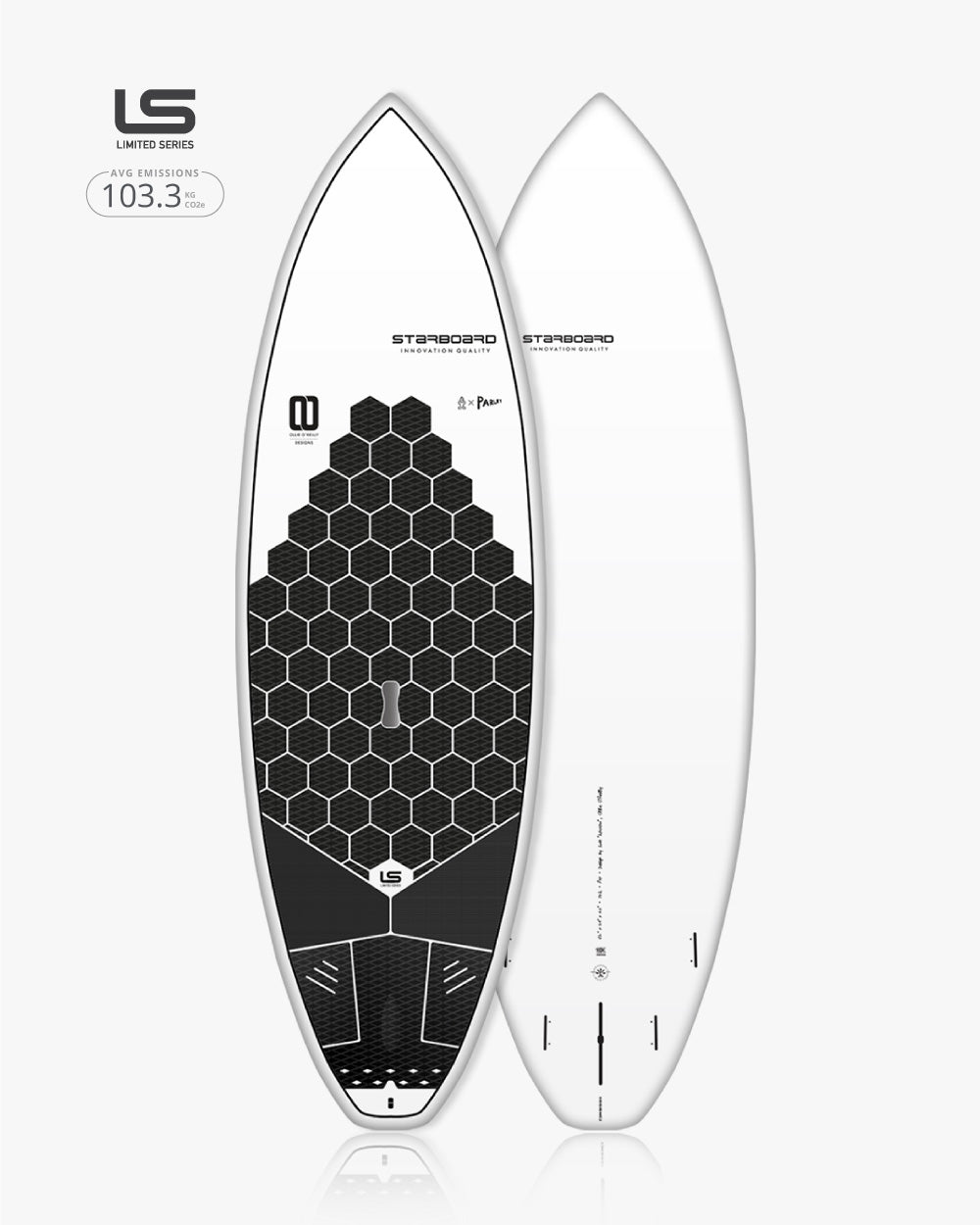

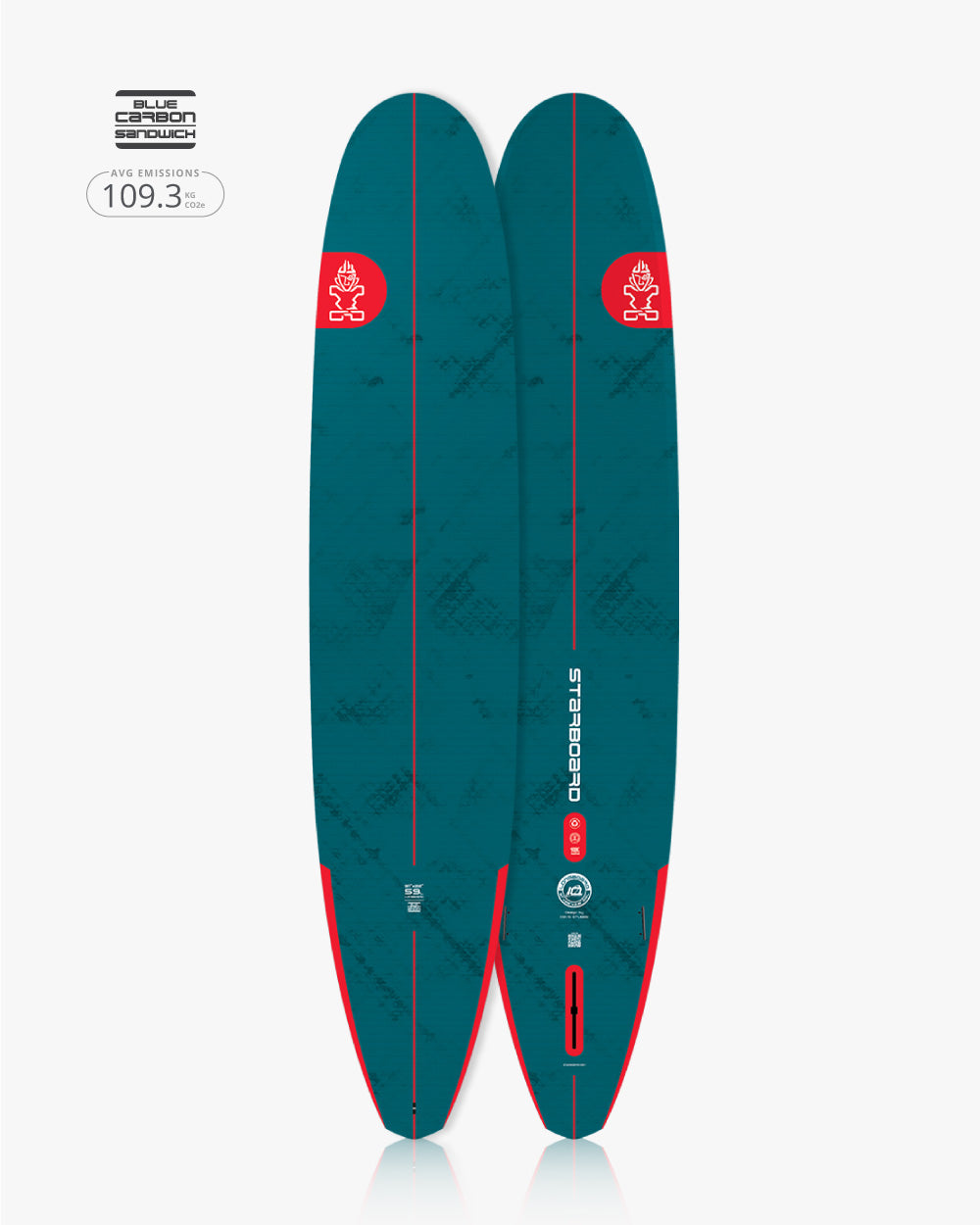

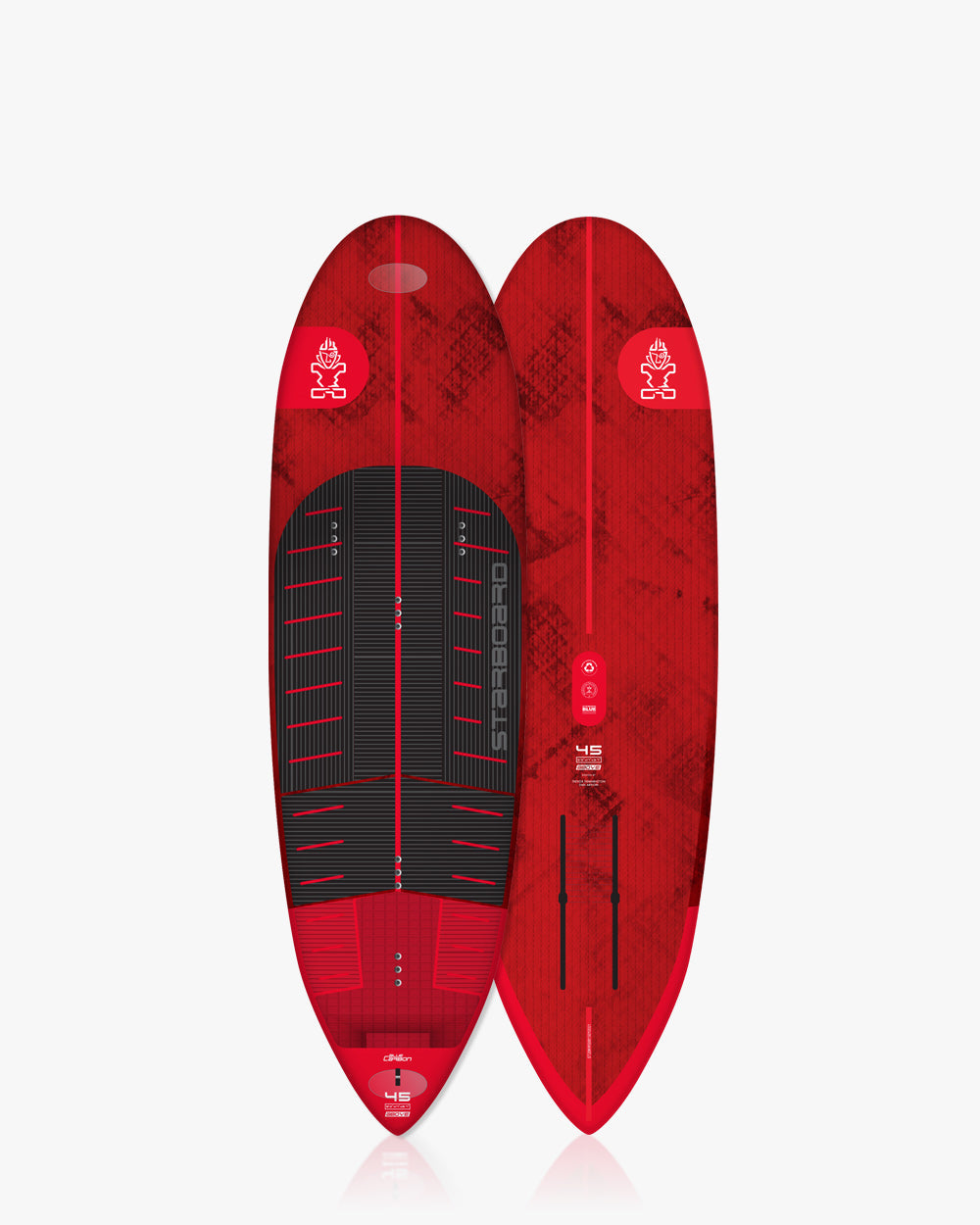

Blue Carbon Sandwich

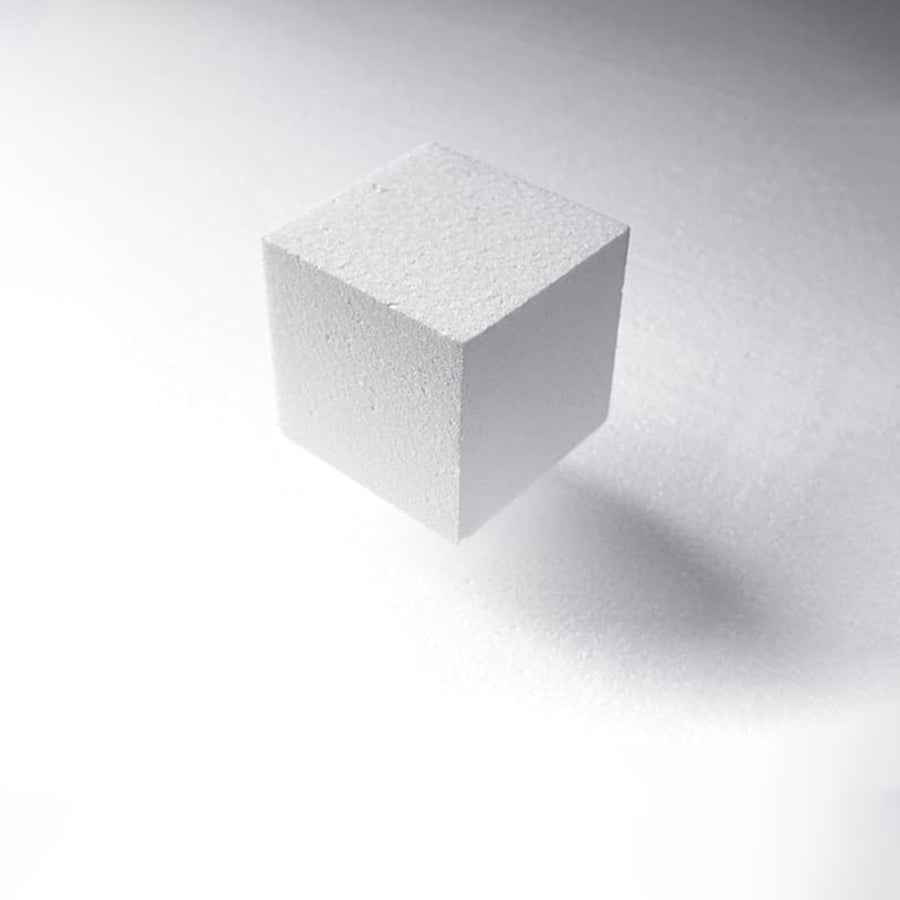

LIGHTEST AND STRONGEST CONSTRUCTION AT THE HIGHEST LEVEL

The Blue Carbon Sandwich Technology we pioneered in SUP 11 years ago has been gradually improved year by year, delivering the fastest & most reactive race machines. Carbon sandwich combines the superior strength and stiffness properties of carbon fiber and PVC foam. This is our premium construction used in the world’s most successful models.

Race boards feature a full PVC standing and full PVC bottom, optimizing reinforcements in the critical areas to keep the weight as light as possible.

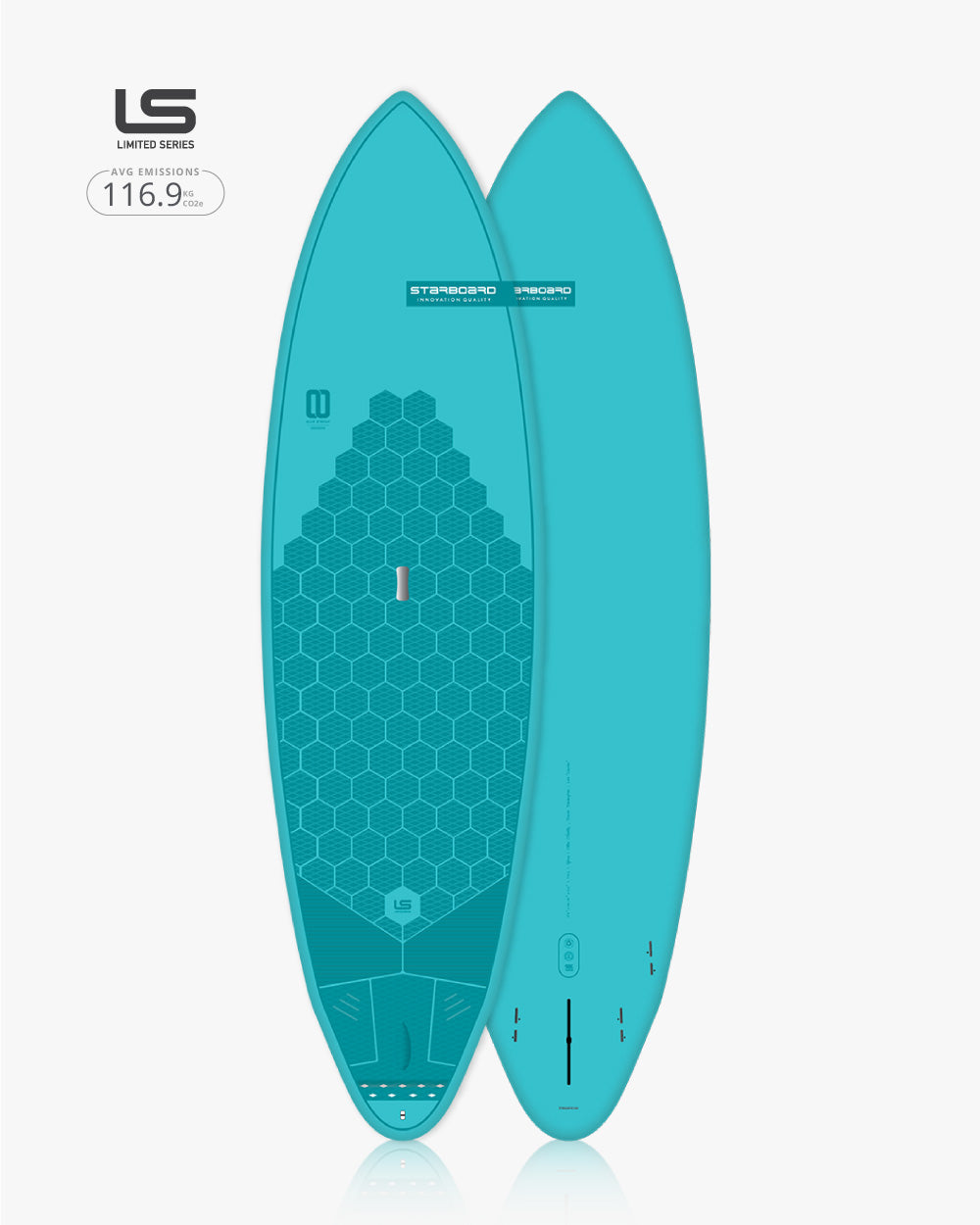

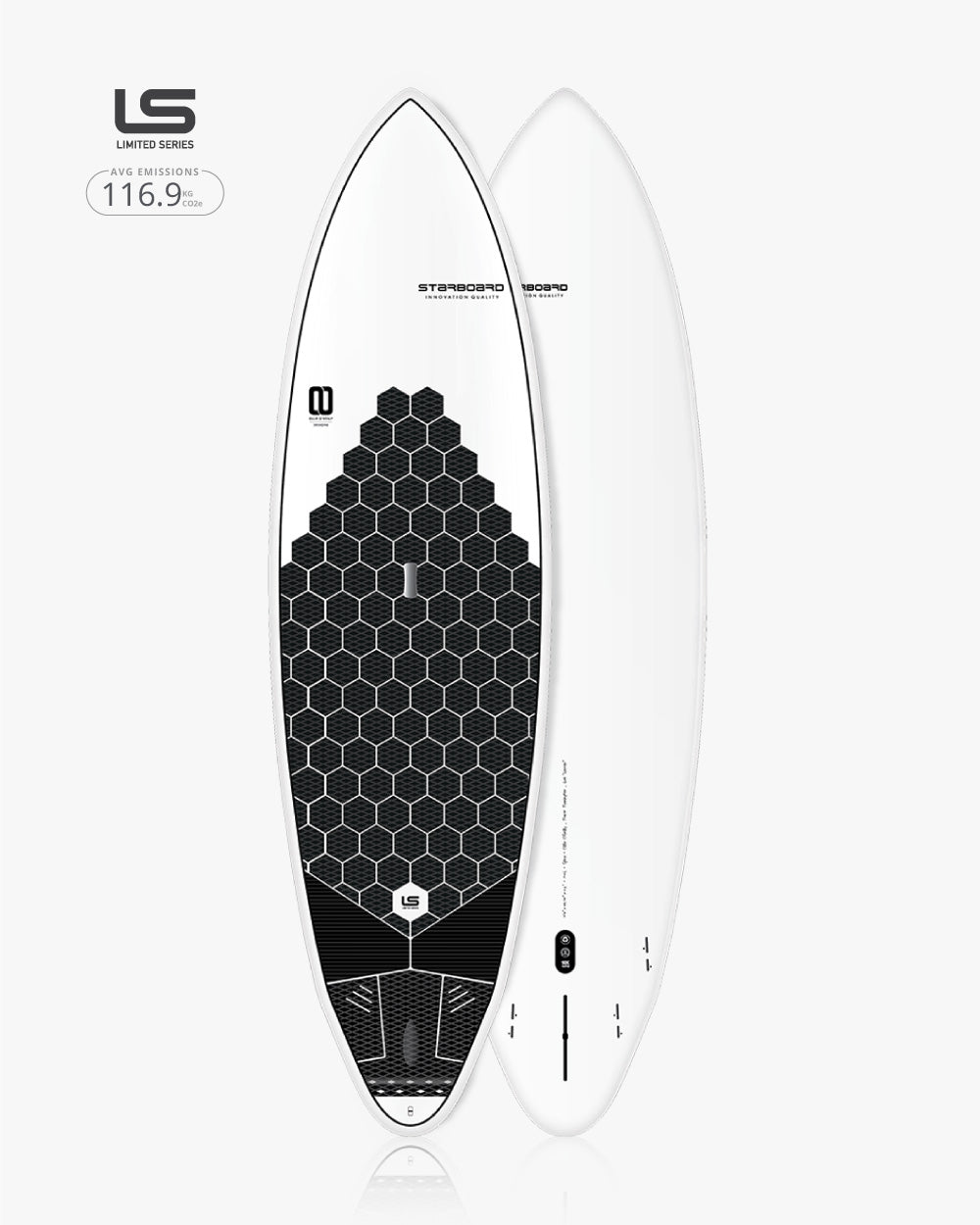

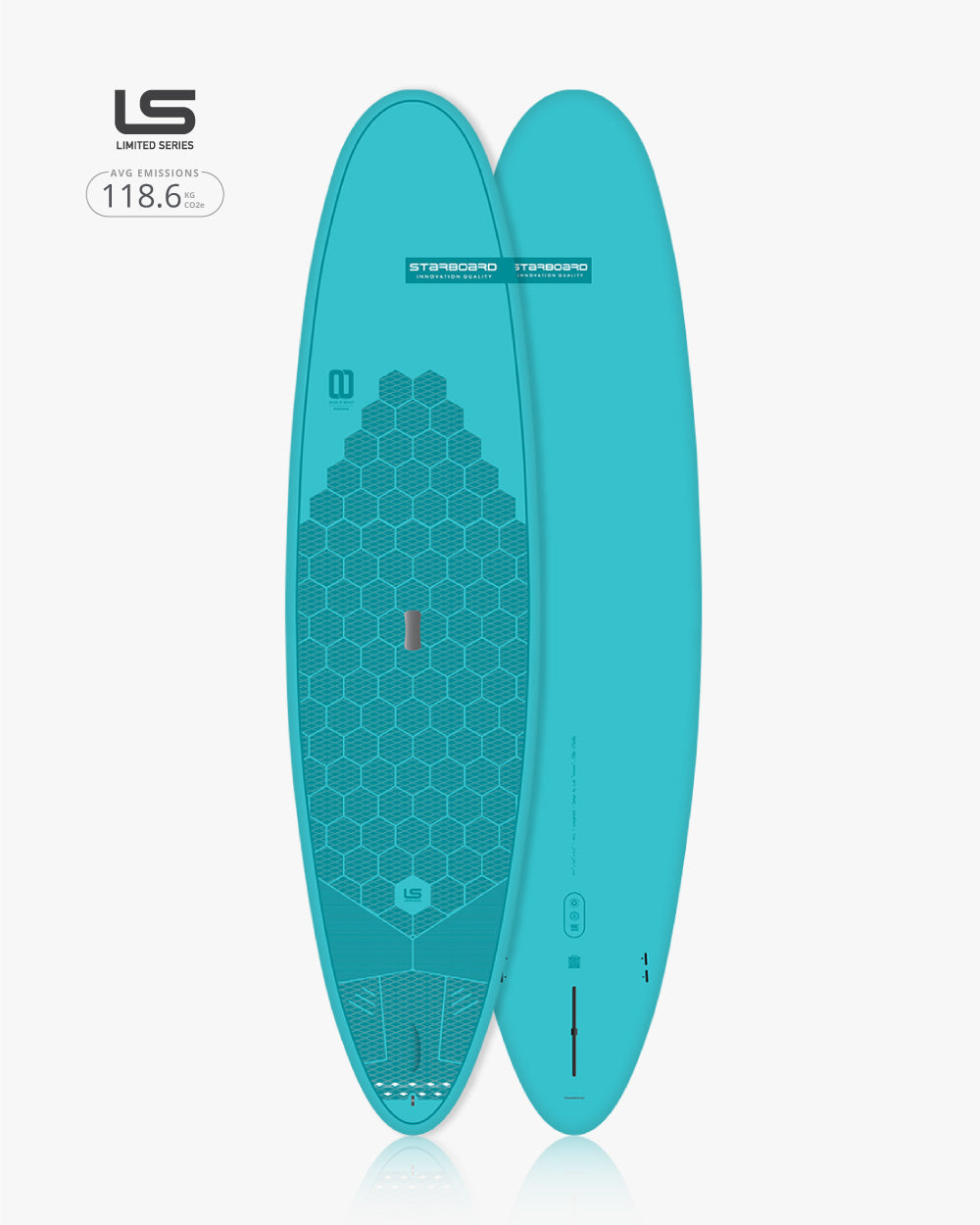

Surf boards feature a full PVC sandwich wrap over the deck, rail and bottom for maximum total breakage strength.